Wood Charcoal Manufacturing Machine – Choosing The Right Machine Wood Charcoal Manufacturing Machine – Choosing The Right Machine

Are you thinking of starting a small business of your own? Do you have access to huge quantities of wood? Have you thought of starting your own charcoal making and selling business? Charcoal is a high quality fuel which is in huge demand. In fact, the demand for high quality charcoal is ever-increasing thanks to the growing demand for charcoal for barbecues and other outdoor stuff.

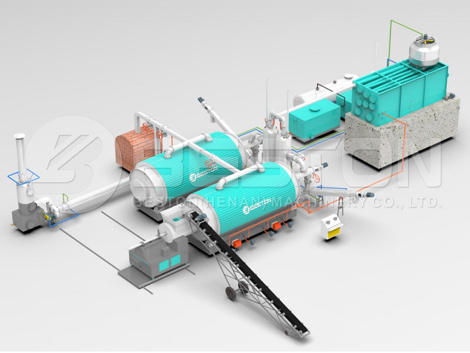

There are many ways of making charcoal from wood but if you wish to turn it into a business and produce high quality charcoal at scale, you need to invest in a wood charcoal manufacturing machine. A simple search online will help you discover hundreds of manufacturers of these machines.

Unfortunately, you can’t trust everything you can find on the manufacturer’s website. Everyone says that their machine is the best and they deserve your money. But you need to take the utmost care when choosing a wood charcoal making machine to set up a solid foundation for your business.

Here are a few tips to help you make the right decision:

Capacity of the Machine

One of the most important factors you need to consider is the processing capacity of the machine. These machines are available in a huge range of capacities. You can find machines capable of processing a few tons of material at a time but those machines are meant to be used at industrial scale plants.

Thankfully, there are also machines with smaller capacity that can be easily set up in a relatively small space. When it comes to choosing the right capacity, you should consider the amount of material available for processing, available space for storage of raw material as well as finished product, and the demand for finished product in your location.

Efficiency of the Machine

Consistently making highest quality charcoal is not easy. Highest quality charcoal sells at a premium in the market and not every machine is capable of providing charcoal of the highest quality. Also, there is a huge difference in efficiency of different designs. Buy a charcoal manufacturing machine that’s proven to have optimum efficiency and is known to produce highest quality charcoal.

Versatility

Even though we are discussing a wood charcoal making machine, it is better to buy a machine that is capable of processing a range of materials. Sometimes, you might have to wait for the wood to dry and in the meantime, there might be some other materials available for processing. This is why, it is important to make sure that the machine you buy can make charcoal out of a variety of materials and not just wood, such as sawdust: https://www.bestongroup.com/sawdust-charcoal-making-machine/.

Price

When it comes to price, don’t look at only the initial cost of the machine. Check the after sales service provided by the manufacturer as well as availability of replacement parts. Choose a machine that is easy to clean and service. Sometimes, the design is too complex for you to reach into various parts of the machine. In such cases, you will become dependent on an expensive service engineer every time you want to replace a part.

To conclude, choosing the right machine for manufacturing wood charcoal is the key to a successful business. Not all the machines available for sale are of the highest quality. This is why, you should carefully check the charcoal making machine for sale versatility, efficiency and capacity in addition to customer reviews and what people have to say about the manufacturer in order to set up a strong foundation for your charcoal business.