Purchase A Suitable Biomass Pellet Making Machine In Just MinutesPurchase A Suitable Biomass Pellet Making Machine In Just Minutes

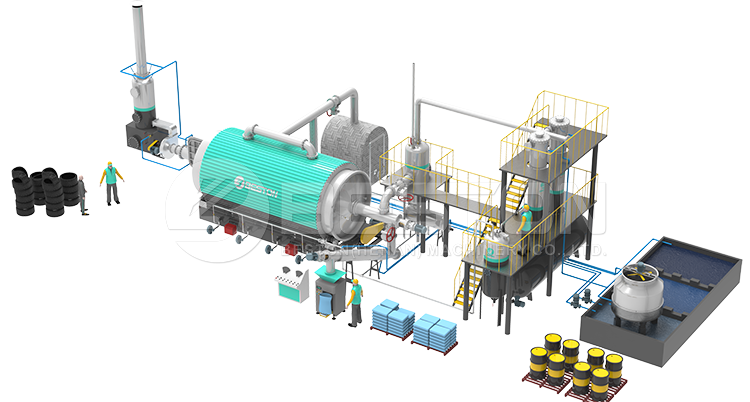

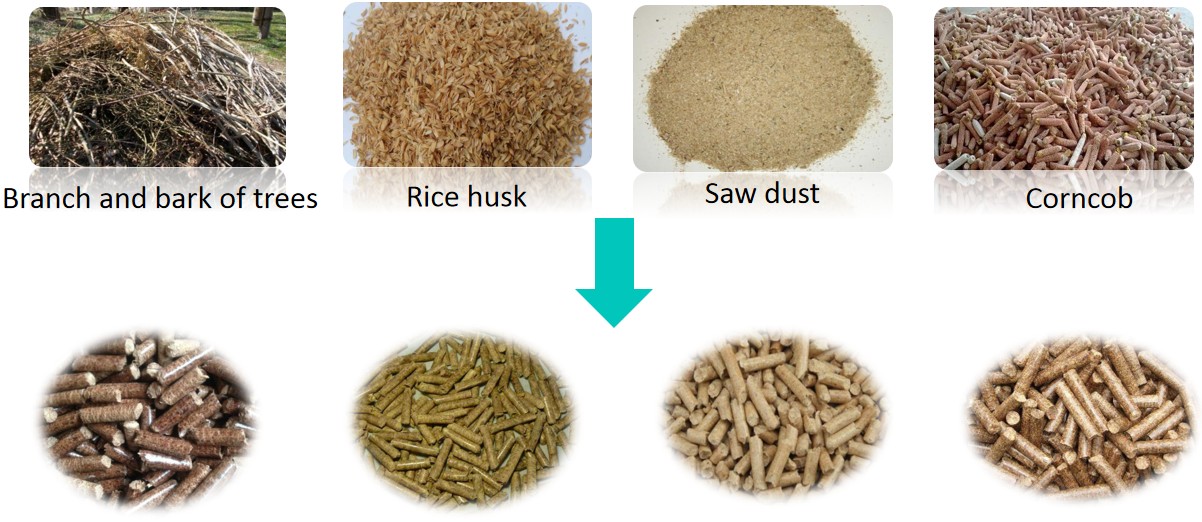

Producing burnable pellets that utilize biomass is a simple thing to accomplish. You will be able to take any form of biomass, including sawdust, and even organic waste, and convert that into burnable fuel within the span of minutes. You have to have the right machine to do this. There are specific pellet making machines that are configured for biomass only. Once you have one or more of these machines producing the biomass for you, you can save a considerable amount of time and money. This is how you can locate some of the top-rated biomass pellet mill.

Where Should You Start Look For Them?

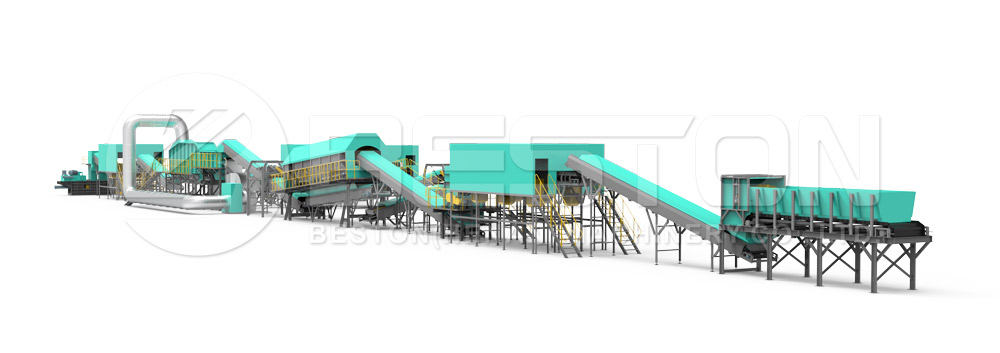

It is important to look for these companies in many different locations. First of all, consider the businesses that are going to sell machines that create biomass. They are located worldwide, some of which are located in Asia which are exceptional. You may find others that are good, but for the price, you simply cannot find a better deal. If you can locate several companies and get a comparative analysis of each one, you can also determine which one is going to be the most efficient. Once that is done, it comes down to how much money you are willing to pay for the wood pellet manufacturing equipment.

How Can You Market These Products?

Marketing the biomass pellets is very easy. That is because so many people, especially during the wintertime, are going to be looking for a source of fuel that is affordable. If they already have a pellet stove that they use for heat, or even cooking, they will be open to getting these from you area it however, it is likely that you will be working with a person in the middle, a distributor that will pay you for a large amount of pellets that you are producing. You will then want to compare the different distributors, how much they are asking for the pellets, and charge them accordingly for these products.

Is This A Sustainable Business?

This is going to be a very sustainable business for anyone that is able to do this regularly. For example, you may not realize how easy it is to set these up, use them to produce biomass pellets, usually to the tune of several tons per day. As long as you have a system for packaging up the pellets, and selling them to local vendors, you can do this on a continual basis. If you are a large-scale business, finding those distributors is really the best way to get all of your money up front and continue to fund your business. Get the pellet making machine cost now.

Biomass pellet making machines are becoming very popular in our world that utilizes different types of fuel for heating. If you are producing these pellets year-round, you can always store them during the warm summer months and you will have plenty to sell to distributors and stores that will buy them from you. If you do have a constant source of biomass, this will be an investment that will pay for itself many times over. These types of pellets are extremely popular right now and you can’t go wrong with this type of investment. See some options on this page – https://dzone.com/users/4436547/bestonmachinery.html.