How Pyrolysis Plants Are Helping Indonesia Manage Its Waste How Pyrolysis Plants Are Helping Indonesia Manage Its Waste

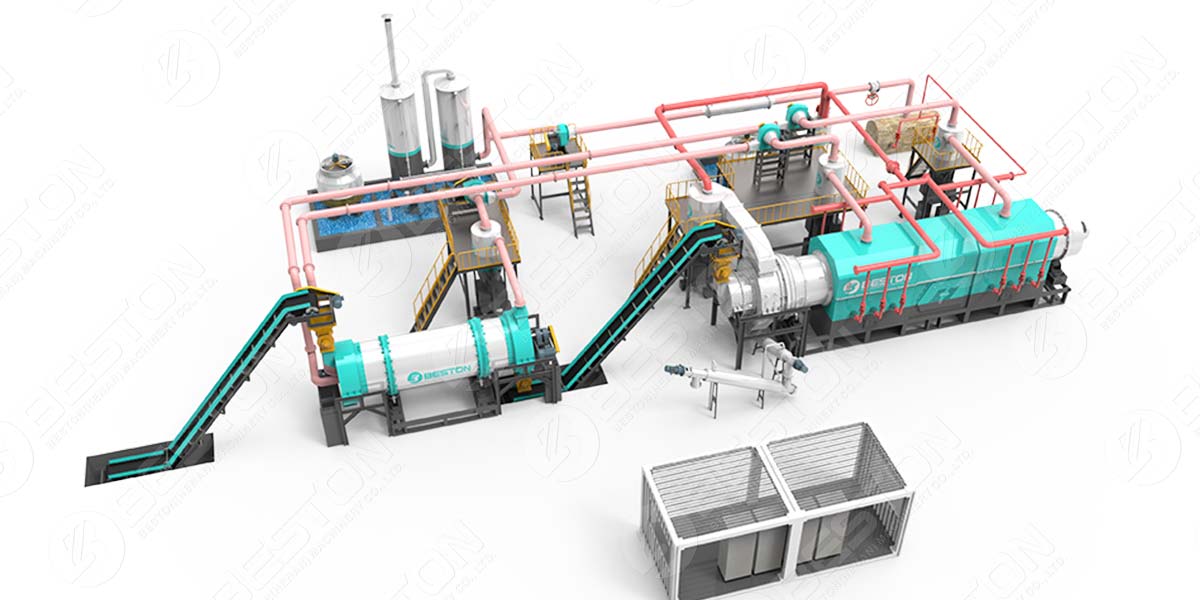

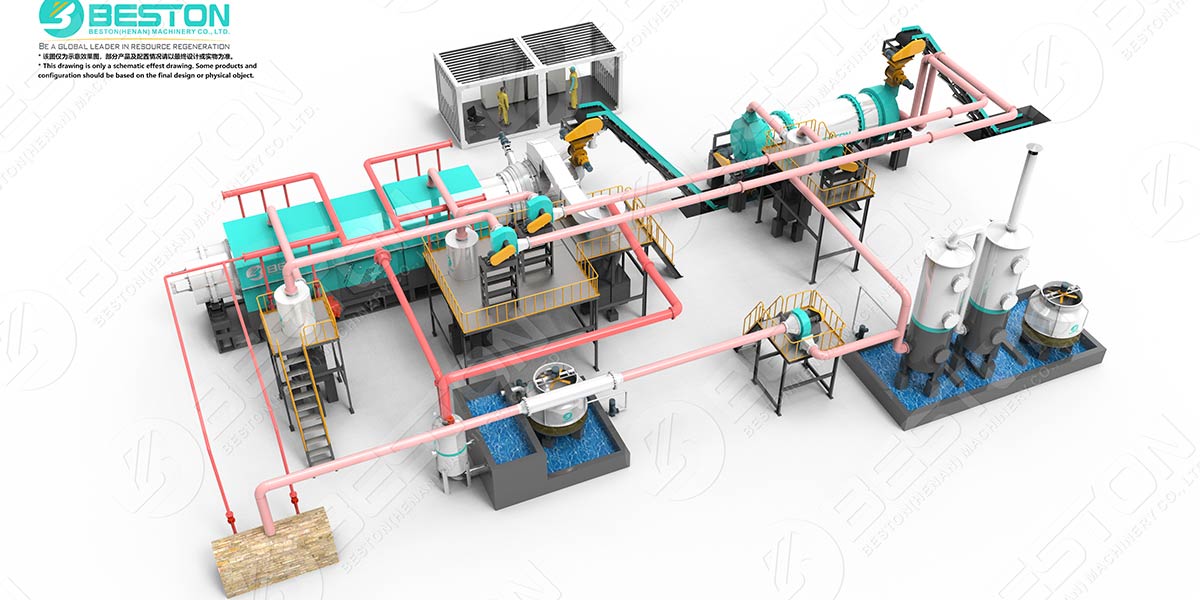

Indonesia is one of the most populous countries in the world, and with this population comes a significant amount of waste. Unfortunately, much of this waste is not disposed of properly and can have a negative impact on the environment. However, with the help of pyrolysis plant in Indonesia, waste materials such as Indonesian waste tire, Indonesian waste plastic, and Indonesian waste oil sludge can be converted into valuable products, mitigating their impact on the environment and even generating profit.

Pyrolysis is a process that involves heating waste materials to high temperatures in the absence of oxygen. This process breaks down the materials into their basic components, which can then be re-purposed for a variety of applications. Pyrolysis plants can be used to process a wide range of waste materials, including Indonesian waste tire, Indonesian waste plastic, and Indonesian waste oil sludge.

One of the most significant benefits of using a pyrolysis plant is that it can help reduce the amount of waste that ends up in landfills. Instead of simply disposing of waste materials, these materials can be transformed into valuable products. For example, Indonesian waste tire can be converted into fuel oil, carbon black, and steel wire. Fuel oil can be used to power machinery, while carbon black can be used to produce high-quality ink and paint. Steel wire can be recycled into new products, reducing the need for virgin steel. Contact Beston to get the mobile pyrolysis unit price.

Similarly, Indonesian waste plastic can be processed into fuel oil, carbon black, and combustible gas. Fuel oil can be used to power industrial equipment, while carbon black can be used to make tires, rubber products, and plastic products. The combustible gas can be used to power the pyrolysis plant, making it self-sustaining.

Indonesian waste oil sludge is another material that can be processed using pyrolysis technology. The sludge is typically a mixture of oil, water, and solids, and can be difficult to dispose of safely. However, with the help of a pyrolysis plant, the sludge can be converted into fuel oil, which can be used to power vehicles and machinery. View the pyrolysis business plan.

In Indonesia, where waste management is a significant challenge, pyrolysis plants can play a critical role in reducing waste and improving the environment. These plants can be operated on a small or large scale, depending on the needs of the community or business. By converting waste materials into valuable products, pyrolysis plants can create new revenue streams and help reduce the environmental impact of waste.

In conclusion, pyrolysis plants are a valuable tool in managing waste materials in Indonesia. They can help transform Indonesian waste tire, Indonesian waste plastic, and Indonesian waste oil sludge into valuable products, reducing the amount of waste that ends up in landfills and generating new revenue streams. With the help of pyrolysis technology, Indonesia can take a significant step forward in reducing waste and improving the environment. If you are interested in this machine, contact Beston – https://bestonmachinery.com/pt/.