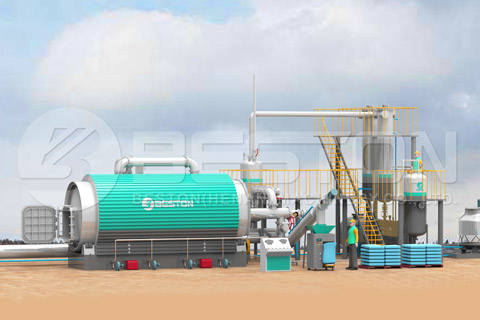

Latest Technology Employed By Pyrolysis Plants For Sale Latest Technology Employed By Pyrolysis Plants For Sale

Have you heard of zero stripping technology? Many businesses think mostly in terms of brand and capacity when purchasing pyrolysis plants for sale. Yet there have been advancements in technology when it comes to the waste pyrolysis plant, too. Do you plan to buy a newer model?

The newer plants are supposed to be more efficient all the way around. That goes for gas leakage, too. While you may find a cheaper deal on a used pyrolysis plant for sale, you may wind up getting more out of a newer model. Would it be possible to actually reduce your capital investment and generate more profits simply by purchasing a newer plant?

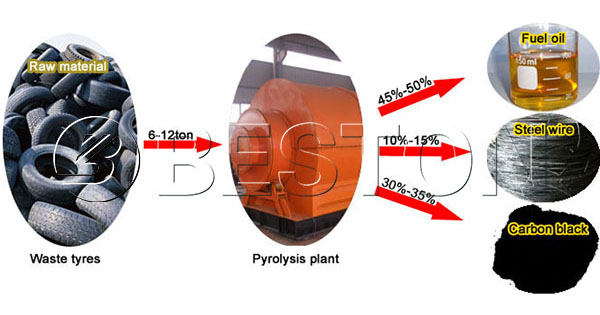

Companies are surely excited about the advancements in technologies when it comes to the tyre oil plant. And it makes you wonder what is to come, too. You’re going to find that with the newer model plants right now, you can count on the majority of the waste rubber being turned into the pyrolysis oil.

The gas is helpful in terms of heating the reactor to be sure. But it’s all about better efficiency of these pyrolysis plants for sale and getting more out of the waste tires and waste plastic. Do you already have a business plan for what you’re going to do with the materials generated from this venture?

Maybe what you do will rub off on other companies in your area, and they will also invest in one of these plants. Recycling all of these waste tires and all of the harmful plastic can be a community effort for sure. Imagine what we could do if we could gather up all the plastic and tire waste and the world and get it recycled. If you wanna get additional info about this machine, click http://bestonturkey.mozello.com.

It makes you wonder why we’re not able to do it now. Perhaps there isn’t a big enough initiative to round it up. Maybe there aren’t near enough of these pyrolysis plants for sale in operation. That tells you, too, that you should be able to keep the machine you by up and running continuously.

You need to a plan to get that waste ready to go. You need a plan for your entire operation. The plan you come up with has everything to do with what capacity you opt for when buying one of these pyrolysis plants. And how long is it going to take you to get a plant in place?

Figure out how long it is going to take you to make back your investment, too. Hopefully you will beat your estimate. Whatever the case may be, you’re going to be smiling about getting rid of the plastic and tire waste out there in your community and perhaps even at your facility. There is no need for it to sit there and harm the environment. Accordingly, purchase it right now: https://BestonTurkey.Com.