Why Investors Are Turning to Charcoal Making Machine Projects in 2025 Why Investors Are Turning to Charcoal Making Machine Projects in 2025

The acceleration of carbon reduction policies, soaring demand for renewable fuel, and heightened focus on waste-to-energy solutions have reshaped the investment landscape in 2025. Among various sustainable technologies, the charcoal making machine project is gaining significant momentum. Investors recognize its potential for scalable profit, low raw material cost, and alignment with global sustainability mandates. With expanding applications in agriculture, metallurgy, power generation, and environmental remediation, the sector presents a pragmatic and future-focused opportunity. Decarbonization strategies have transitioned from voluntary actions to compliance-driven frameworks. Governments are endorsing carbon-negative technologies, making the sawdust charcoal machine a compelling industrial solution. Operating through controlled thermal decomposition, the biomass pyrolysis reactor transforms forestry residues, agricultural waste, and organic by-products into solid carbon-rich charcoal. These machines deliver not only renewable energy but also permanent carbon sequestration potential, strengthening their appeal to environmentally inclined investors. Projects using wood charcoal manufacturing machine or sawdust charcoal machine capitalize on readily available biomass resources. Agricultural residues such as rice husks, bamboo shavings, corn stalks, and sawdust are inexpensive, abundantly available, and renewable. Minimal pre-treatment processes reduce operational expenditure. This feedstock advantage ensures stable production cycles and high ROI, particularly in regions with extensive agricultural production. The industrial relevance of charcoal has evolved. It is no longer restricted to household fuel or small-scale heating. Charcoal products from biochar pyrolysis machine are utilized in fertilizer enhancement, soil remediation, metal smelting, activated carbon production, and even energy storage systems. Biochar improves soil structure, enhances microbial activity, and increases water retention capacity, making it valuable to agricultural enterprises seeking higher yields. Metallurgical uses also continue to grow, especially in steel, silicon, and alloy manufacturing sectors that demand high-calorific and low-sulfur carbon material. Carbon credit markets continue to expand, attracting diverse investor participation. Charcoal projects derived via biomass pyrolysis reactor can qualify for multiple environmental certifications, including biochar carbon removal credits. As these credits are categorized as high-quality and long-lasting due to their stable sequestration properties, their market value remains significantly higher than traditional offset credits. Investors achieve dual benefits—monetary returns and ESG portfolio enhancement. Contemporary wood charcoal manufacturing machine models feature advanced thermal control systems, continuous feeding design, automated discharging, and intelligent PLC monitoring. These innovations reduce energy loss, minimize manual labor, and enhance conversion efficiency. High-temperature reactor insulation, optimized gas recycling, and upgraded condensing systems enable near-zero-waste production. Non-condensable gases are recirculated for combustion, significantly improving thermal efficiency and reducing external fuel dependency. Developing regions in Africa, Southeast Asia, Eastern Europe, and Latin America are rapidly adopting charcoal making technologies due to rising energy costs and increasing demand for cleaner heat sources. For investors, this presents a diversified market entry strategy with high scalability. The ability to implement modular production lines allows gradual investments while maintaining operational flexibility. Charcoal making machine projects represent a rare convergence of sustainability, profitability, and technological maturity. They deliver tangible environmental benefits while maintaining commercially attractive payback periods. In 2025, investors are no longer searching for theoretical eco-projects—they are choosing scalable, verifiable, and future-compatible solutions. The charcoal making machine stands out as exactly that kind of solution.Transition Toward Low-Carbon and Circular Economies

Capitalizing on Abundant Feedstock Accessibility

Expanding Commercial Applications

Attractive Environmental Incentives and Carbon Credits

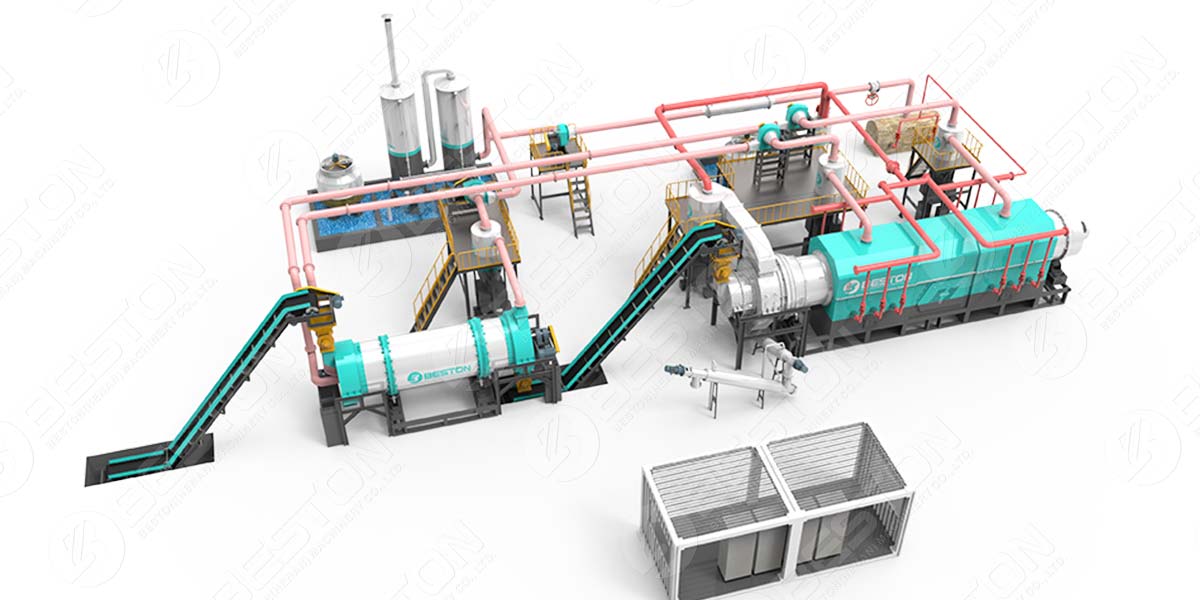

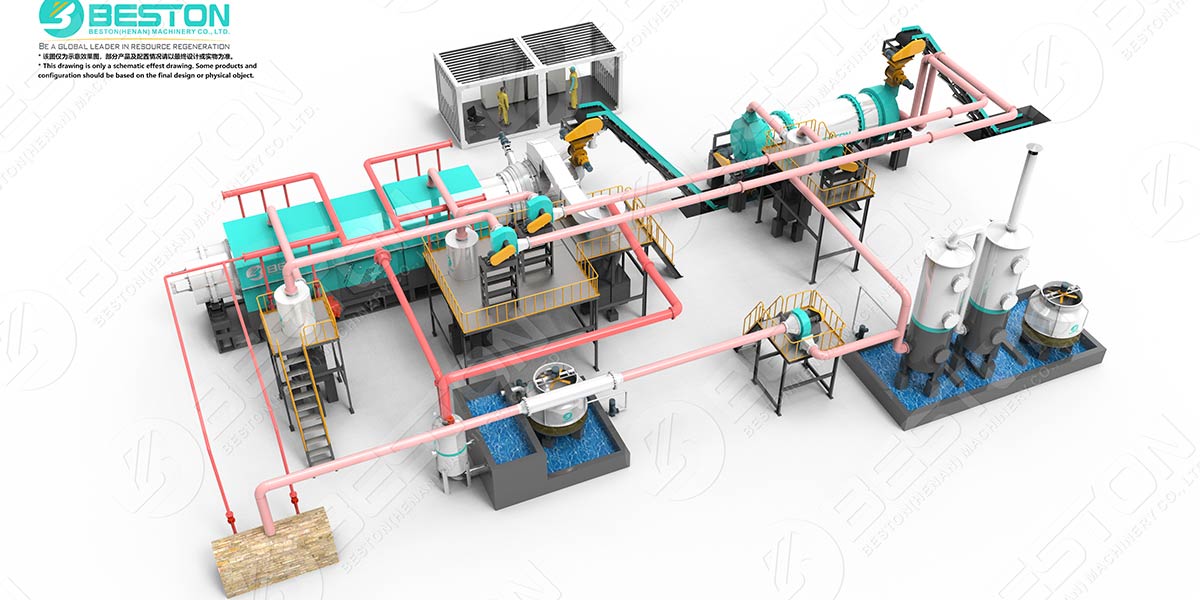

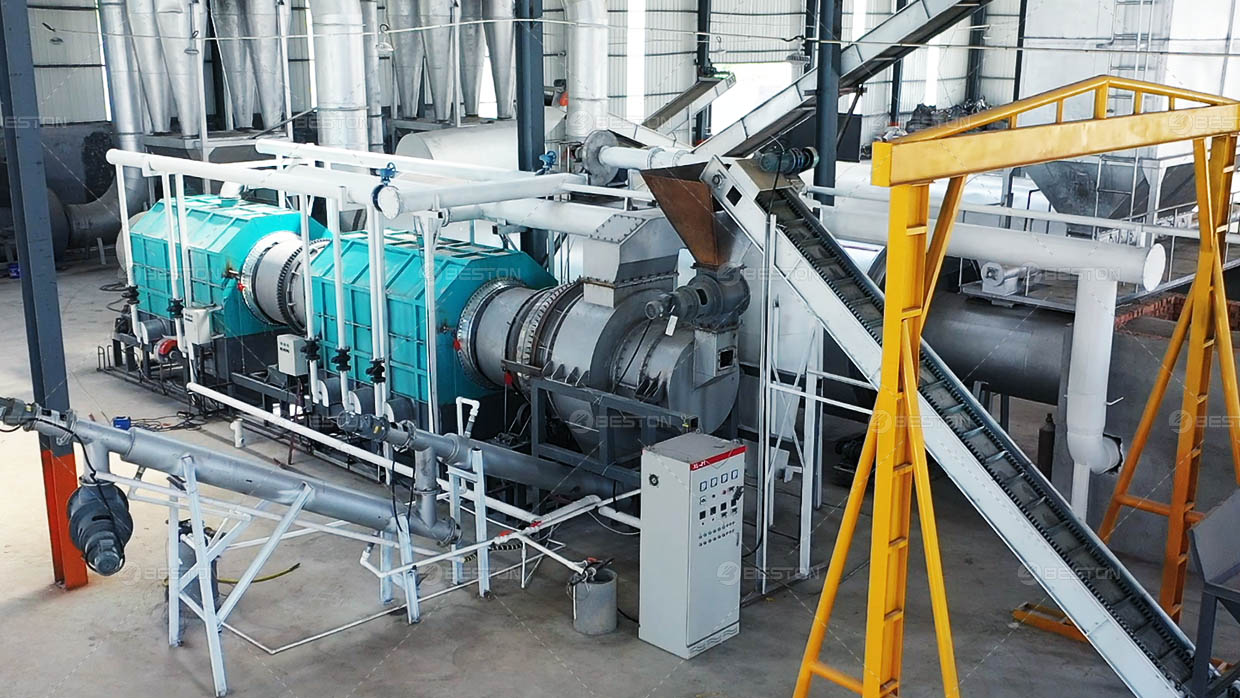

Technology Innovation Driving Higher Efficiency

Strong Market Prospects Across Multiple Regions

Long-Term Economic and Environmental Viability