Beston Tyre Pyrolysis Plant: Revolutionizing Waste Management and Energy Production

In a world increasingly focused on sustainability and environmental preservation, effective waste management has become a critical concern. Among the various types of waste, end-of-life tyres pose a significant challenge due to their non-biodegradable nature and the sheer volume generated each year. Beston Tyre Pyrolysis Plant offers a groundbreaking solution to this problem, transforming waste tyres into valuable resources while minimizing environmental impact. This blog delves into the features, benefits, and operational aspects of Beston tyre pyrolysis plant, highlighting why they are a top choice for businesses and municipalities worldwide.

Understanding Tyre Pyrolysis

Tyre pyrolysis is a process that involves the thermal decomposition of waste tyres at high temperatures in the absence of oxygen. This process breaks down the tyres into smaller molecules, resulting in the production of valuable by-products such as pyrolysis oil, carbon black, steel wire, and syngas. These by-products can be further refined and utilized in various industrial applications, making tyre pyrolysis an eco-friendly and economically viable solution to tyre waste management.

Key By-Products of Tyre Pyrolysis

- Pyrolysis Oil: This oil can be refined into various types of fuels, including diesel and gasoline, or used as a feedstock in chemical industries.

- Carbon Black: This solid residue can be used as a reinforcing agent in rubber products, as a pigment in inks and paints, or as a raw material for the production of activated carbon.

- Steel Wire: Extracted from the tyres during the pyrolysis process, steel wire can be recycled and used in the steel industry.

- Syngas: The gas produced during pyrolysis can be used as a source of energy for heating the pyrolysis reactor or can be converted into electricity.

Beston Tyre Pyrolysis Plant: Features and Benefits

Beston Group(https://www.bestongroup.com/) is a leading manufacturer of waste recycling equipment, including tyre pyrolysis plants. Beston’s plants are known for their high efficiency, advanced technology, and compliance with environmental standards. Here are some key features and benefits of Beston Tyre Pyrolysis Plants:

Advanced Technology

Beston Tyre Pyrolysis Plants are equipped with state-of-the-art technology that ensures efficient and environmentally friendly operation. The plants feature a fully enclosed and continuous operating system that minimizes human intervention and maximizes automation. This advanced technology results in higher conversion rates, better quality by-products, and lower emissions.

Energy Efficiency

Energy efficiency is a crucial aspect of Beston’s tyre pyrolysis plants. The plants are designed to utilize the syngas produced during the pyrolysis process to heat the reactor, reducing the need for external energy sources. This self-sustaining energy system not only lowers operating costs but also minimizes the plant’s carbon footprint.

Environmental Compliance

Beston Tyre Pyrolysis Plants are designed to meet stringent environmental regulations. The plants are equipped with advanced emission control systems that ensure the release of minimal pollutants. These systems include dust removal, water spray, and activated carbon adsorption, ensuring that the pyrolysis process is environmentally friendly and compliant with local and international standards.

Versatility

One of the standout features of Beston’s tyre pyrolysis plants is their versatility. The plants are capable of processing a wide range of tyre types, including passenger car tyres, truck tyres, and even off-the-road (OTR) tyres. This flexibility makes Beston’s plants suitable for various waste management scenarios, from small-scale operations to large municipal waste processing facilities.

Comprehensive Support and Maintenance

Beston Group offers comprehensive after-sales support and maintenance services to ensure the smooth operation of their tyre pyrolysis plants. This includes installation, training, and ongoing technical support. Beston’s commitment to customer satisfaction ensures that any issues are promptly addressed, and the plant operates at optimal efficiency.

Economic Viability

Investing in a Beston Tyre Pyrolysis Plant can be economically viable due to the revenue generated from the sale of by-products such as pyrolysis oil, carbon black, and steel wire. Additionally, the reduction in disposal costs and the potential for carbon credits make Beston’s plants an attractive investment. The advanced technology and energy-efficient design further enhance the plant’s profitability. Work out the pyrolysis plant cost estimate here.

Operational Aspects of Beston Tyre Pyrolysis Plants

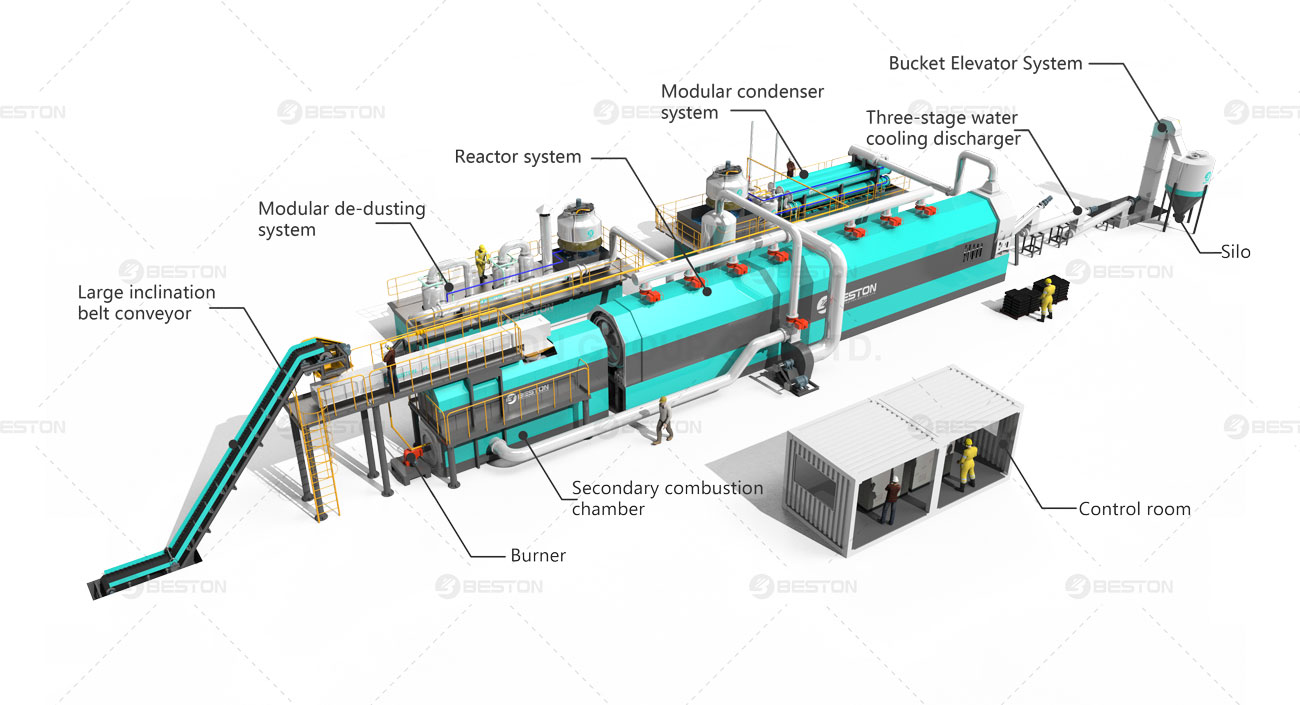

Understanding the operational aspects of Beston’s tyre pyrolysis plants is crucial for potential investors and operators. Here’s a detailed look at the process and key components involved:

Feedstock Preparation

The first step in the pyrolysis process is the preparation of the feedstock. Waste tyres are shredded into smaller pieces to facilitate efficient thermal decomposition. This pre-treatment step ensures that the tyres are evenly heated during the pyrolysis process, resulting in higher conversion rates and better quality by-products.

Pyrolysis Reactor

The heart of the pyrolysis process is the reactor, where the thermal decomposition of the tyres takes place. Beston’s reactors are designed to operate at high temperatures in the absence of oxygen, ensuring complete decomposition of the tyres. The reactors are equipped with advanced temperature control systems that ensure optimal operating conditions and maximize the yield of valuable by-products.

Condensation System

The gases produced during the pyrolysis process are passed through a condensation system, where they are cooled and condensed into pyrolysis oil. Beston’s condensation systems are designed for maximum efficiency, ensuring that a high percentage of the gases are converted into liquid oil. The remaining non-condensable gases are utilized to heat the reactor, creating a self-sustaining energy system.

Emission Control

Beston Tyre Pyrolysis Plants are equipped with advanced emission control systems that ensure minimal environmental impact. These systems include dust removal, water spray, and activated carbon adsorption, which effectively remove pollutants from the exhaust gases. The result is a clean and environmentally friendly operation that complies with stringent environmental regulations. See the project site of pyrolysis plant in Nigeria.

By-Product Collection

The by-products of the pyrolysis process, including pyrolysis oil, carbon black, and steel wire, are collected and processed for further use. Beston’s plants are designed to efficiently separate and collect these by-products, ensuring high purity and quality. The collected by-products can be sold or utilized in various industrial applications, generating additional revenue for the plant operator.

Conclusion

Beston Tyre Pyrolysis Plants represent a significant advancement in the field of waste management and energy production. By transforming waste tyres into valuable resources, these plants offer an eco-friendly and economically viable solution to the global tyre waste problem. Beston’s commitment to advanced technology, energy efficiency, environmental compliance, and comprehensive support makes their tyre pyrolysis plants a top choice for businesses and municipalities worldwide.

Investing in a Beston Tyre Pyrolysis Plant is not only a step towards sustainable waste management but also a profitable business opportunity. With the ability to process a wide range of tyre types and generate valuable by-products, Beston’s plants offer a practical solution to the challenges of tyre waste disposal. As the world continues to focus on sustainability and the circular economy, Beston Tyre Pyrolysis Plants are poised to play a crucial role in shaping a cleaner and more sustainable future.